Gray is the predominant color in the relatively young field of 3D printed concrete applications. What is often overlooked is that colorful construction projects can be easily realized by using inorganic pigments. For the reliable coloration of 3D printed concrete, iron oxide pigments are the perfect choice.

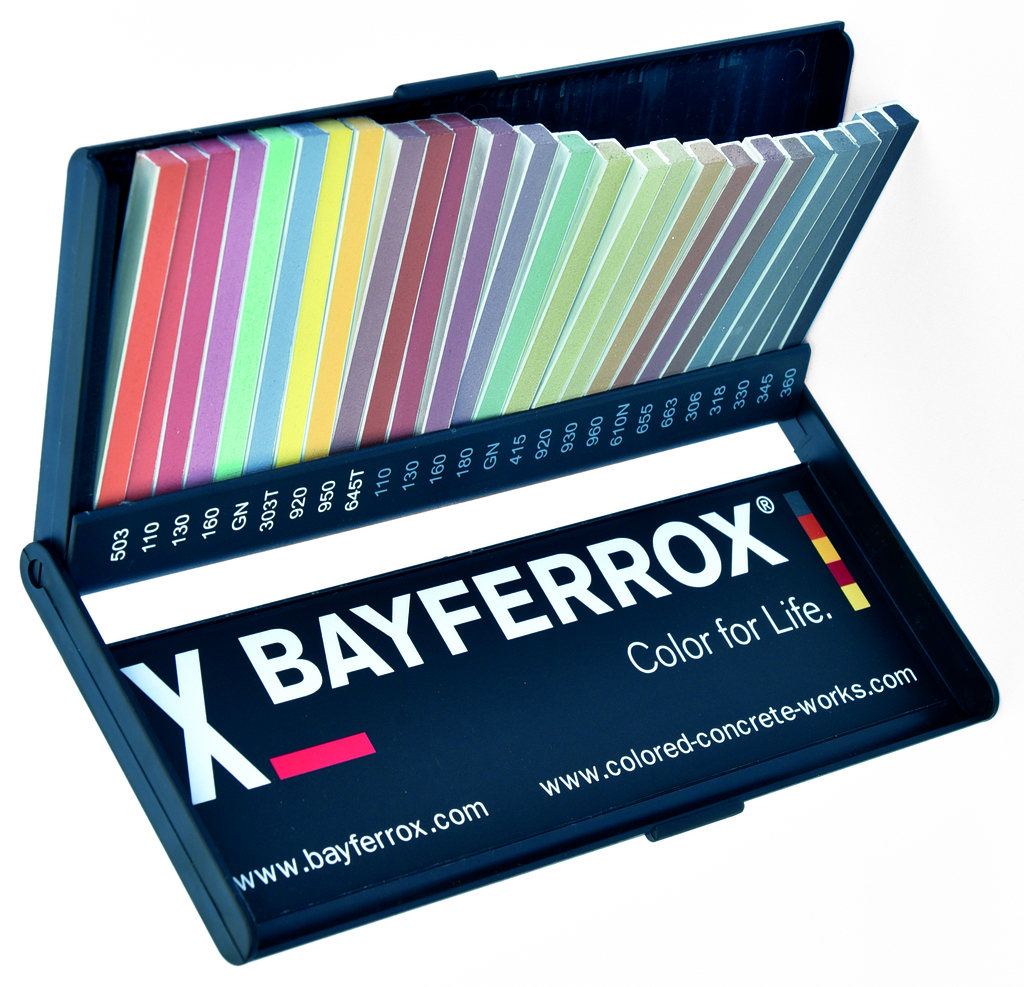

Lanxess supports its customers in adding color to their 3D printed concrete products. The specialty chemicals company has created a sample box showing which colors can be realized in additive manufacturing. The box contains concrete samples in 26 different colors, colored with weather-resistant, colorfast, inorganic pigments from the well-known Bayferrox brand. These can be used for reliably adding color to 3D-printed concrete structures, lending users of this highly promising and cost-efficient technology even greater design freedom in projects large and small.

Creating colorful highlights with inorganic pigments

The Bayferrox pigments, which are highly renowned in the construction industry, are available in 100 shades of black, red, yellow, brown and green and are suitable for use in reinforced and non-reinforced concrete. Inorganic iron oxide pigments in particular have proven their suitability for use in various concrete construction materials over many years in extensive tests and weathering tests. Due to their chemical composition and structure, these products are not only insoluble in water and dilute acids, resistant to lime and alkalis, but also absolutely weather- and light-stable and thus ideally suited for coloring building materials.

However, expert advice concerning the use of pigments is essential for colored 3D printing projects. Ensuring that the concrete is of exactly the right shade even after it has cured depends not only on the quality and mixing of the pigments, but also on the application itself. The type of cement used affects the shade – and vice versa. How the pigments react to the concrete additives used also needs to be taken into account. This process requires extensive knowledge of how the concrete and color pigments interact.

Knowing the optimum pigmentation level, for example, is a significant factor in reducing costs. If the amount of pigment in a concrete mix is steadily increased, then the color intensity initially increases linearly with the pigmentation. As the pigment addition progresses, however, the range is reached at which the addition of further quantities of pigment no longer causes any significant intensification of the color shade and is therefore uneconomical. The definition of the saturation range depends, among other things, on the system parameters of the concrete; in general, however, addition rates above five percent (based on the binder quantity) are not necessary for the very strong Bayferrox pigments. In the case of pigments with a weaker color, on the other hand, the saturation range is only reached with much higher pigment additions. The amount of pigment required to achieve a certain color shade can thus become so large that this increase in the amount of fines has a negative effect on the concrete's technological properties.

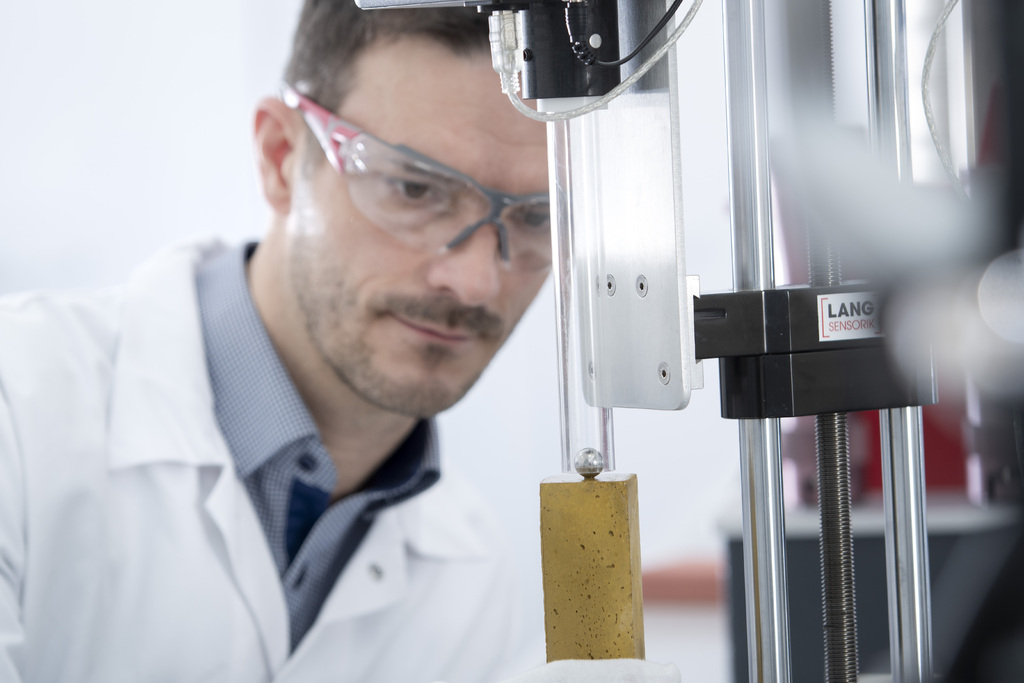

Lanxess offers manufacturers of 3D-printed in-situ & precast concrete objects expert technical support to ensure that drab gray does not come to dominate the relatively new world of 3D concrete printing. The company has recently expanded its application technology laboratory for construction materials and the technical center for pigment applications at its production site in Krefeld-Uerdingen, Germany. With an area of roughly 1,000 square meters, the facility is equipped with state-of-the-art technology. This center of excellence offers extensive testing and analysis of the physical properties of the pigments as well as their effects in concrete:

Color matching to meet customer specifications can be made in existing and new concrete formulations by using modern color measuring technology. Accurate measurement of the precise color coordinates are determined on the basis of the CIELab color system for all cement based applications.

Colorimetric problems in customer-specific applications can be analyzed reliably under the electronic microscope. The cause of the problem is often determined by analyzing the shape of the primary pigment particles and their distribution in the hardened concrete structure.

Consistency checks in the usage of iron oxide ensure trouble-free processing of the concrete at the customer as well as reproducible coloring. Lanxess prepares recommended recipes for its customers which take into account the raw materials used and process equipment available.

Consistency checks in the usage of iron oxide ensure trouble-free processing of the concrete at the customer as well as reproducible coloring. Lanxess develops and recommends tailormade recipes for its customers which take into account the raw materials used and process equipment available.

The color sample box can be requested by 3D concrete printers free of charge at http://3d.bayferrox.com.