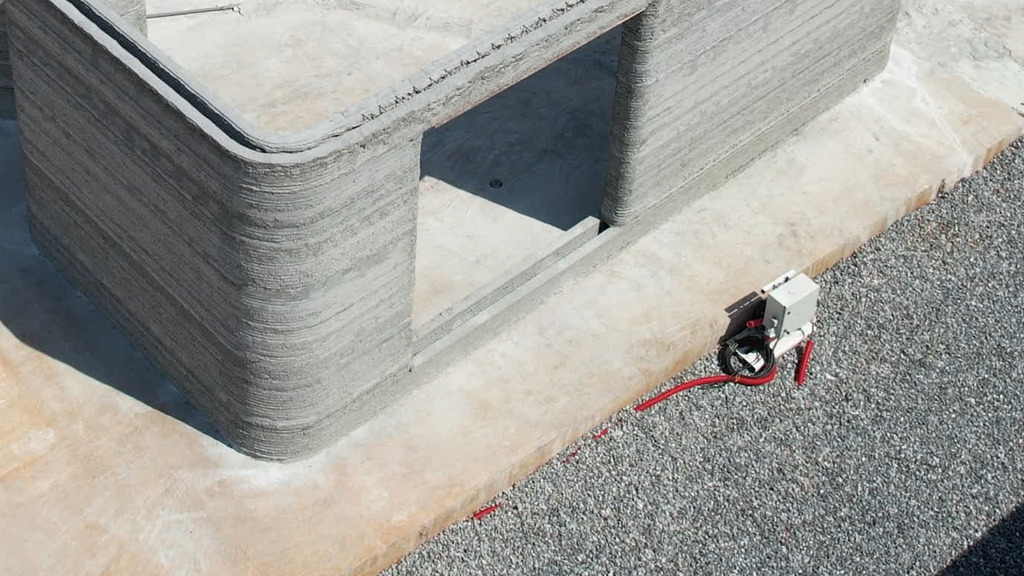

Power2build have recently finished their largest 3D printed building with a Cobod Bod2 construction printer in Angola. The company has set out to transform the housing market and are pioneers aiming to solve affordable housing in Angola with 3D printed buildings.

The house is the second 3D printed residential building in Angola. It is a 140 m2 house that holds a suite, two bedrooms, three bathrooms, a dining room, and a living room. As the three bathrooms indicate, this is not a social housing project, but rather a house showcasing the design and architectural possibilities of 3D printed buildings.

Power2build is working with Cobod’s 3D printing technology to significantly reduce the housing shortage in Angola. The 3D printing technology is an innovative method that allows construction of affordable and high-quality housing in the region in a faster and more competitive way.

.jpeg.jpg)

Ricardo Almeida, CEO from Power2Build said: “We are very proud of our progress; people were questioning if we couldn’t print bigger. We have now printed a 2,6 times bigger house and in about 2/3 of the time compared to the first house. We improved the speed of execution remarkably, but still believe there is room for improvement. In the future we will only become better at mastering this technology. We are getting more efficient by the day and closer to achieving our vision to deliver better housing at affordable prices to Angolan families.”

The 3D printed house was done with the D.fab material solution, an additive mix developed by Cobod and Cemex, that enables printing with real concrete.. D.fab enables the usage of 99% locally available materials and only 1% Magic Mix supplied by Cobod. 3D printing with real concrete is a genuine step change in the industry of 3D construction printing and serves as a prominent gateway to properly commercializing the technology.

Commenting on the successful build of the house, Henrik Lund-Nielsen, Founder & General Manager of Cobod International said: “We are proud to have made the technology for this project. Power2Build have increased their speed of execution tremendously compared to their first and now second project. This is a great example of how we and our customers are continuously improving the technology and can build faster, better, and cheaper as our customers and partners become experts at mastering the 3D printing technology.”

www.cobod.com

.jpeg.jpg.jpg)